Optimisation of energy usage and power system uptime in Precision Manufacturing

A Soul Implementation Case Study: Eliminating Downtime and Uncovering Power Reliability Gaps in High-Value Equipment Operations

Project Snapshot

Introduction

This case study explores how a precision equipment manufacturing industry utilised Soul to address persistent operational inefficiencies and power quality issues. Despite having top-notch facilities and backup systems, the plant faced rising energy costs and unexpected downtime of critical high-value equipment. Soul provided the critical predictive insight needed to transition from reactive fixes to proactive optimization.

Operational Context

The industry operated with high-grade infrastructure, boasting more than 20 pieces of precision machinery, each valued between USD 100k and 500k. The management had invested significantly in facility quality, including backup machinery implementation to mitigate production risks.

However, observation revealed a disconnect between equipment operation and actual production needs. The facilities were largely operating at full machine capacity despite production requirements not necessitating such intensive usage. This misalignment suggested underlying inefficiencies that standard operational oversight had failed to catch.

Key Challenges

Manual audits conducted by the management team uncovered several critical issues that were affecting both the bottom line and operational stability:

3.1 System Instability & Downtime

The production line faced frequent tripping of power systems. These interruptions caused unexpected downtime and disruptions in machine operations, directly impacting productivity and potentially risking damage to sensitive precision components.

3.2 Disproportionate Energy Costs

Despite periods of low production volume, the facility experienced consistently high energy consumption. More alarmingly, the trend showed an 8% year-over-year increase in energy bills, signaling worsening efficiency that could not be explained by production output alone.

3.3 Limitations of Reactive Support

While on-site technician support was always available, their mode of operation was inherently reactive. Interventions were "post-event fixes"—addressing problems only after they had already caused disruption. The management recognized the need for a better, proactive approach.

3.4 Inadequacy of Standard Solutions

Over a period of six months, the team experimented with various solutions mixing software and IoT. While these provided Energy Management System (EMS) dashboards useful for external audits, they offered a "live display" of problems without providing the diagnostic capabilities needed to actually fix them.

Why Soul?

When the management team encountered Soul, they identified a distinct advantage over previous solutions. The deciding factor was the platform's RIPE (Resilience Intelligence and Power Effectiveness) approach.

- Pre-Event Recognition: The ability to recognise issues before an electrical fault of any nature, not just limited to overloads or arc faults, but various set of power issues that current circuit breakers cannot prevent today.

- Hidden Loss Detection: A bonus capability to identify unnoticed energy losses that were silently inflating bills, enabling the facility to utilise the power effectively.

Implementation & Findings

Soul was deployed directly at the power supply points of critical machines and designated facility zones.

Images showing Soul devices installed on critical machinery power supplies

Upon activation, Soul began monitoring plant operations in real-time. The system successfully identified root causes of potential failures before they manifested as downtime events.

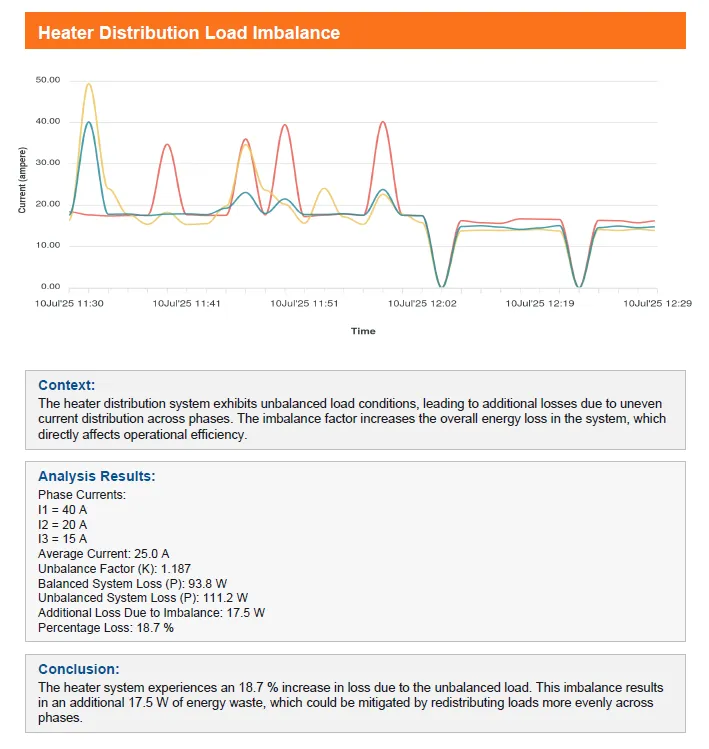

Visuals/Screenshots from the Soul platform identifying specific faults and energy anomalies

Conclusion

For high-value precision manufacturing, this shift from reactive maintenance to proactive intelligence was transformative. By deploying Soul, the facility moved beyond simple energy monitoring to diagnosis and actionable fault prevention via the RIPE approach. This implementation not only safeguarded expensive machinery from electrical damage but also brought visibility to hidden operational inefficiencies, paving the way to reverse the trend of rising energy costs and making their power systems reliable at all times.